In LED lighting technology, constant current drive is the key to achieving efficient and stable light source output. Compared with traditional incandescent or fluorescent lamps, LEDs are extremely sensitive to changes in current. Even a small current fluctuation may cause LED brightness to be unstable, and even seriously affect its life. This is why constant current drive has almost become a standard feature in professional lighting products.

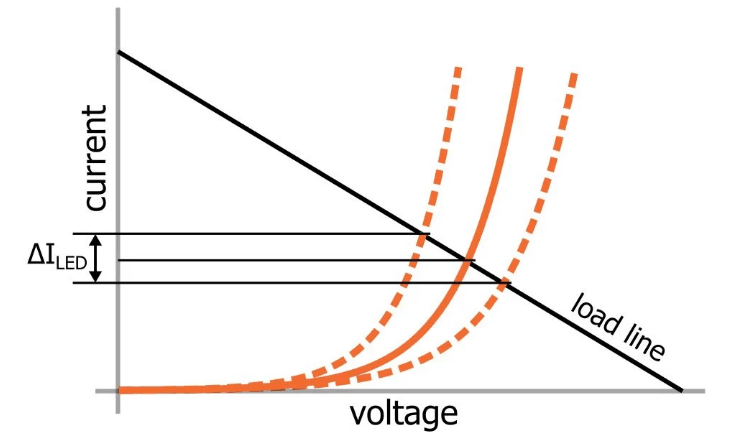

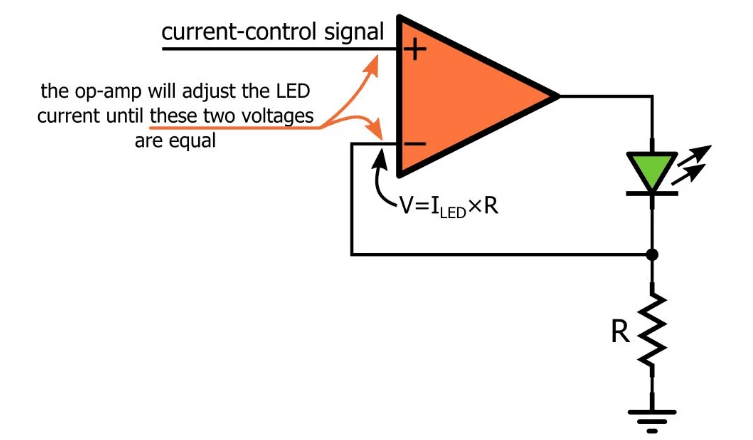

In terms of physical properties, LED is a current-driven component with a very steep volt-ampere characteristic after forward conduction. Simply put, once it exceeds its conduction threshold, the current will rise very quickly, while the voltage change is very small. Therefore, if the LED is driven only by providing a fixed voltage, the current may surge due to a slight increase in voltage, thereby burning the LED chip. The basic principle of constant current drive is to continuously monitor the output current through the internal control circuit, and automatically adjust the output voltage according to the change of load to keep the current constant at all times.

There are many ways to implement constant current drivers, from the simplest current limiting resistor, to the linear current stabilization circuit, to the more complex and efficient switching power supply circuit. Among them, the switching constant current drive is the current mainstream solution, especially suitable for medium and high power LED applications. It usually adopts buck, boost or buck-boost circuit structure, and works with control chip, MOSFET, inductor and sampling resistor and other components to maintain stable output current, reduce volume and heat loss while ensuring high conversion efficiency.

The control chip plays a vital role in the entire drive system. It detects the voltage on the sampling resistor to determine whether the output current deviates from the set value, and immediately adjusts the on-time of the main switch MOSFET to achieve the purpose of dynamic current stabilization. At the same time, a good constant current driver also integrates short-circuit protection, over-temperature protection, soft start and other functions to ensure safety and reliability in complex working environments.

In comparison, although the linear constant current driver has a simple structure and low cost, it is difficult to be competent for high-power applications because its excess energy is mainly consumed in the form of heat, has low efficiency, and generates severe heat. It is usually used in low-power lighting or cost-sensitive products, such as night lights or low-brightness indicator lights.

It is worth noting that in actual design, choosing a constant current driver is not as simple as looking at the current output value. Designers also need to consider the forward voltage range of the LED, the voltage adjustment capability of the driver, the thermal management design, and the product's use environment. For example, in a system with multiple LEDs in series, the constant current driver needs to provide a sufficient voltage range to cover the total voltage drop of all LEDs. At the same time, to avoid overheating and runaway, a reasonable heat dissipation structure and temperature feedback mechanism are also an indispensable part of the driver design.

By using constant current drive, we can not only obtain consistent and stable lighting effects, but more importantly, we can significantly extend the service life of the LED light source, reduce light decay, and reduce maintenance costs. This is crucial for construction site lighting, commercial lighting, floodlights, road lights and other occasions with extremely high reliability requirements.

In general, constant current drive is not only a guarantee for the safe operation of LED lighting systems, but also the technical foundation behind high-performance lighting products. It represents a comprehensive control capability of light quality, energy efficiency, and safety, and is the invisible core behind every excellent LED lamp.